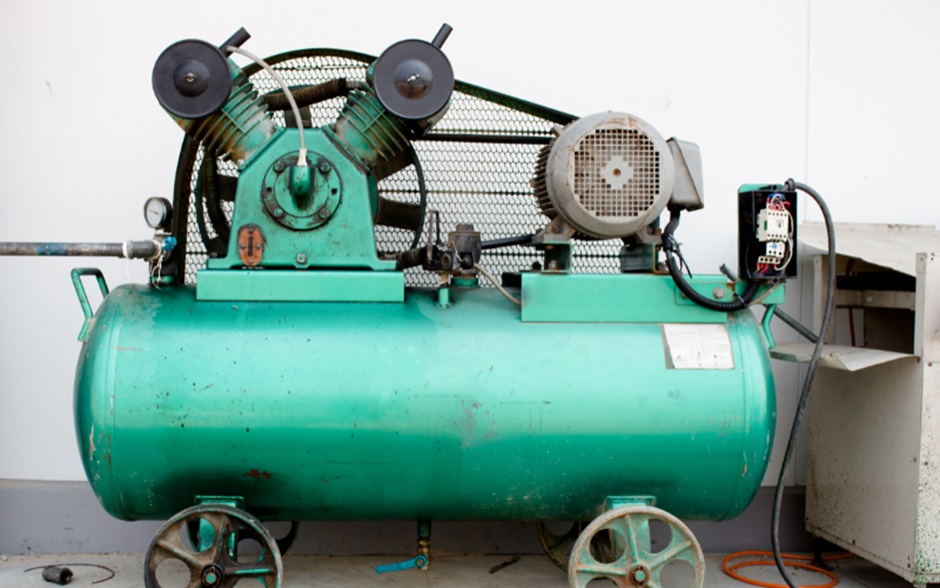

Air compressors are among the most critical tools in various industries, as they power machines and equipment. However, the compressor is another mechanical device prone to malfunction unless taken care of accordingly. Regular service keeps the machine running well with minimal chances of breakdowns. Ignoring minor issues until later may result in major ones requiring expensive repairs or machine replacement.

Let us look at some common warning signs of air compressor problems and find out when you should seek air compressor servicing in Singapore. We will help keep your machine running smoothly and extend its lifespan!

1. Unusual Noises

Unusual sounds from your air compressor during operation are one of the earliest warning signs that something is going wrong. Of course, air compressors make some degree of noise; however, there are sounds one should look out for: sounds that could indicate loose parts, worn components, or mechanical failure.

Take immediate action when there are weird sounds that you’ve never heard before because they can signal underlying problems. Regular servicing of an air compressor in Singapore will make early detection and elimination of such problems.

2. Low Pressure

If you feel a sudden pressure drop that your air compressor produces, know that something is wrong. The decrease in air pressure may arise due to several problems (e.g. blocked air filter, faulty valves, leaking tank). Once the compressor cannot reach the intended pressure level or takes longer than usual to build up the pressure, the performance deteriorates.

The most common causes of pressure drops are clogged or dirty air filters. Precautions should be taken by regularly changing and checking filters to ensure air flows properly. Ignoring low air pressure can reduce the performance of your equipment; this results in poor output of tools and machinery.

3. High Temperature

Sick of red flags? Well, another red flag is overheating! The machine suffers from large-scale wear and tear due to excessive heating, which can reduce its lifespan. An overheated compressor could be the result of different types of problems, ranging from low levels of oil inside the compressor, malfunctioning cooling systems, or overworking the machine in general.

These are two reasons why cooling mechanisms must be installed on air compressors, and any failure in this system might lead to overheating. Low oil or dirty oil filters might also cause temperatures to rise since the compressor relies on its oil for lubrication and cooling. When your air compressor repeatedly overheats, it’s time to call for maintenance or perhaps find a used air compressor for sale in Singapore—sometimes they work well and are cheaper alternatives!

4. Leaks or Contamination of Oil

Oil is crucial for air compressors in lubricating the motor. So, if you notice oil leaks around the compressor or contamination, then you have to get up on your toes! It means there’s a problem. Damaged seals or gaskets can cause leaking oil indicating failures of the oil separator or poor maintenance practices. Low or contaminated oil levels could lead to serious damage in an air compressor due to insufficient lubrication of internal components-increasing friction with the generation of overheating.

Regularly monitoring oil levels and their condition can prevent these problems. If you find oil leakages around or suspect their contamination, it is time to seek a technician who specialises in air compressor servicing in Singapore.

5. Air Leaks

The most common complaint with air compressors, which certainly can lead to significant degradation in their performance, is air leaks. Even small leaks can result in losses of pressure, making the machine work harder to meet the output. The outcome is inefficiency, increased consumption of energy, and wear that is quite unnecessary on the compressor.

The most common sources of leaks are damaged hoses, faulty seals, or even cracks in the compressor tank. Sometimes leaks are not readily observable, so one needs to listen for the hissing sound. In the process, finding leaks as early as possible prevents further damage and reduces operational costs.

If you suspect there is an air leak, it would be better to call a professional. A professional in air compressor servicing in Singapore will be able to find the leak and seal the spot for your air compressor to work more effectively.

Air compressors may be essential tools in many fields, yet all mechanical things need a bit of TLC to function continuously. Keeping an eye out for signs of trouble, such as unusual noises, decreased air pressure, overheating, and oil leaks can help prevent little problems from blossoming into issues. Regular servicing will ensure that your compressor enjoys a longer lifespan while guaranteeing that it works well.

Whether you are facing problems with your air compressor or need regular servicing, contact Beng Chuan Machine today! We will do our best to help maintain your compressor to be at its best for many more years to come.